Rapid Prototyping 3D Printing Services

3D printing rapid prototyping services

Our 3D printing service allows you to 3D print custom parts on demand. we offer comprehensive 3D printing services that allow you to 3D print custom parts quickly and affordably. Whether you need cheap 3D printing service options or advanced solutions like resin 3D printing service, metal 3D printing service, or SLS 3D printing services, we have the expertise to meet your needs.

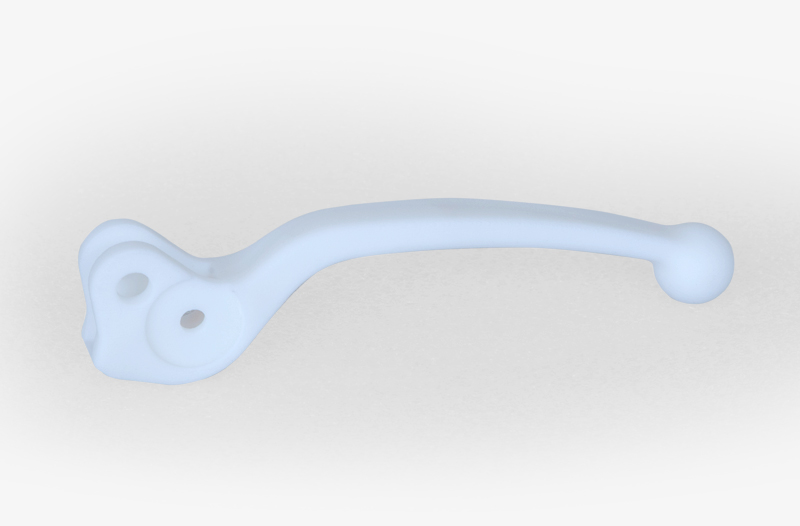

Stereolithography (SLA) Resin 3D Printing Service

SLA 3D printing service for rapid prototyping. Multiple thermoset resin materials available.

Stereolithography (SLA) is a revolutionary 3D printing process that provides rapid prototyping services with its high precision and superior detail.This technology uses a UV laser beam to build a 3D solid model by curing a liquid photosensitive resin layer by layer according to a computer-aided design (CAD) model.

The SLA process not only enables stunning accuracy and detail, but also offers a wide range of material options, including transparent, opaque and rigid resins, to meet the needs of different application scenarios. Its extremely high feature resolution and high-quality surface finish make SLA-printed models extremely visually and tactilely appealing.

Our SLA 3D printing services provide unmatched precision and superior detail. Whether you require custom 3D printing services or resin 3D print service, we can produce high-quality parts for various applications

SLA 3D printing technology has a wide range of application areas, mainly including:

– High-precision parts manufacturing: the high-precision nature of SLA technology is ideal for manufacturing precision parts that require strict tolerance control.

– Appearance prototyping: SLA-printed prototypes have excellent surface quality and are able to realistically reproduce the details and texture of the design, making them ideal for product appearance design verification.

– Shape and fit testing: SLA technology can quickly print complex geometric shapes to help engineers perform design verification and functional testing to ensure part compatibility and assembly.

In addition, SLA technology is widely used in the following areas:

– Jewellery design: SLA printing can produce delicate jewellery models, offering designers the possibility of rapid iteration and modification.

– Medical devices: In the medical field, SLA technology is used to create customised medical devices and human implants, improving the personalisation and precision of treatments.

– Cultural Arts: Artists and designers use SLA technology to create unique artworks and decorations that showcase personalised creativity and aesthetics.

SLA 3D printing technology, with its rapidity, flexibility and efficiency, is continuing to drive innovation and development in a variety of fields, including manufacturing, healthcare and the arts. By choosing SLA 3D printing services, you will be able to quickly turn your ideas into reality and experience unprecedented design freedom and manufacturing flexibility.

Industrial parts metal 3d printing services

Metal 3D printing technology is revolutionising the traditional manufacturing industry with its superior precision and flexibility. Our Selective Laser Melting (SLM) process is not only an innovative industrial metal 3D printing technology, it’s also a powerful tool for quickly realising high-quality prototypes and production parts.

In as little as 7 days or less, we can produce fully functional, high-performance metal prototypes and production parts for you. This technology breaks through the limitations of traditional manufacturing, enabling a wide range of metal materials to be transformed into final products suitable for end-use applications.

Our aluminum 3D printing service and 3D metal printing service are revolutionizing industries by delivering high-performance, functional prototypes and production parts.

Our metal 3D printing technology is used in a wide range of applications, including but not limited to:

Mould making: using 3D printing technology, we can quickly produce complex mould designs, significantly shortening development cycles and reducing costs.

Complex Geometry: Metal 3D printing technology can accurately produce complex geometries that are difficult to achieve with traditional processes, providing designers and engineers with unlimited room for creativity.

Reducing metal parts in assembly: Through integrated design, we can reduce the number of parts and simplify the assembly process, thereby increasing productivity and product reliability.

We understand that every project is unique. Therefore, we offer customised solutions to meet your specific needs in terms of design, material selection and post-processing. Our team of experts will work closely with you to ensure that every detail meets your high standards.

By choosing our metal 3D printing services, you will gain not only technical support, but a bridge to innovation and excellence. Let’s explore the endless possibilities of metal 3D printing together and turn your ideas into reality.

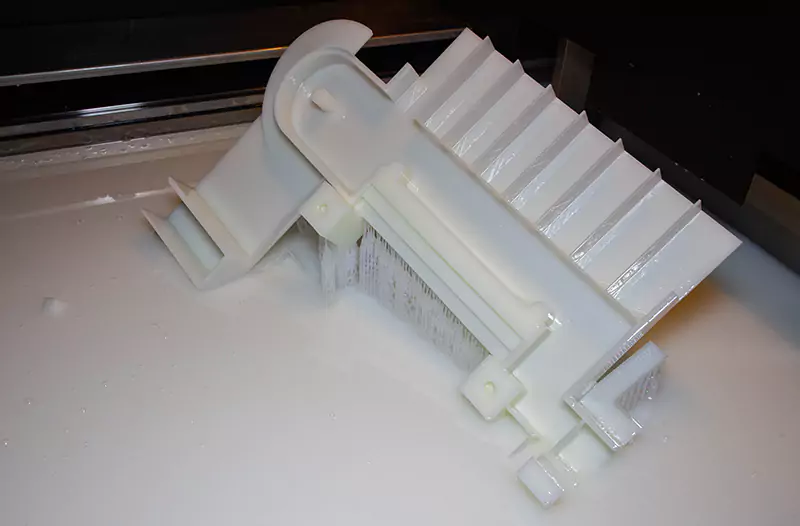

Selective Laser Sintering (SLS)

Selective Laser Sintering (SLS) is an advanced, industrial-grade 3D printing technology known for its rapid manufacturing capabilities and superior material compatibility.The SLS process enables a rapid transition from design to solid by using a high-powered laser beam to selectively melt a powdered material and build out a 3D object layer by layer.

Our SLS 3D printing services are ideal for producing durable, functional parts with complex geometries.

The advantages of SLS 3D printing technology are:

–No support structure required: Compared to traditional 3D printing technology, no additional support structure is required during SLS printing, which greatly simplifies the post-processing process and increases printing efficiency.

Multi-Part Nested Printing: SLS technology allows multiple parts to be nested into a single build, and this batch printing capability is a cost-effective solution for industries that need to produce 3D printed parts in large quantities.

Common uses of SLS technology include, but are not limited to:

Jigs and Fixtures: SLS printed jigs and fixtures feature high precision and complex geometries to meet the diverse needs of industrial production.

Housings and Protective Covers: Using SLS technology, housings and protective covers with complex internal structures, which are often characterised by lightweight and durability, can be rapidly manufactured.

Snap and moving parts: SLS technology enables the manufacture of snap and moving parts with high-precision fits, which play an important role in mechanical design and assembly.

In addition, SLS technology is widely used in the following areas:

Automotive industry: In automotive manufacturing, SLS technology is used for rapid prototyping and the production of functional parts, accelerating the development process of new models.

Aerospace: SLS technology is used in aerospace to create lightweight, high-strength components that help improve the performance and fuel efficiency of aircraft.

MEDICAL DEVICES: SLS technology enables medical devices and implants to be tailored to the specific needs of patients, providing personalised treatment options.

By choosing SLS 3D printing technology, you will be able to enjoy a seamless transition from design to manufacturing, enabling rapid product iteration and innovation. Let’s explore the endless possibilities of SLS technology and turn your ideas and needs into reality.

Why Choose Us?

- Cheap 3D Printer Service: Affordable pricing without compromising quality.

- Quick Turnaround: Parts delivered within days with rapid prototyping services.

- High Quality: Precision in every project, from 3D prototype printing services to large 3D printing services.

- Customized Solutions: Tailored to your requirements, from material selection to post-processing.

Applications of Our 3D Printing Services:

- 3D Model Printing Service: High-quality models for presentations or testing.

- 3D Printing Jewelry Service: Create intricate designs with SLA or SLS technology.

- Plastic and Metal Prototyping: Low-cost 3D printing service for industries like aerospace, automotive, and healthcare.

Get a Quote Today!

Looking for the cheapest online 3D printing service? Need help with rapid 3D printing services or 3D printing service quotes? Contact us now and let’s bring your ideas to life with cutting-edge 3D printing metal services, nylon 3D printing service, and more.

Related Cases

No posts found!